A Measure of Quality

“This porridge is too hot, this porridge is too cold, this porridge is just right”

Goldilocks knew exactly what she wanted. Even if she’d not shared her requirements with the bears beforehand. However the measures made were fairly subjective.

In other situations it is much more important to get the mix right. Try building a sand castle with sand that is too wet, or too dry and the product fails, and that’s not just an opinion. If that was part of a concrete mix for a new building, you’d want to be sure it was “just right”.

What Is Quality?

What constitutes ‘quality’ will vary by product and stakeholder. Some may consider a luxury leather bound volume a ‘quality’ product. It would be wasteful and excessive to use such an expensive resource to write shopping lists. It would be more appropriate to use it to record pledges of office for city officials that will be kept in a permanent archive.

Quality may be best judged by the longevity of writing preserved in the volume’s pages. It will be of little use if its writings fade to invisibility in a few years. Copies of the Magna Carta written on parchment have lasted for over 800 years. This would be unlikely had it been written on cellulose based paper with a disposable ball point pen.

How Do You Measure It?

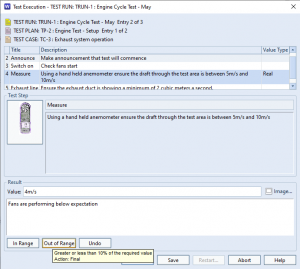

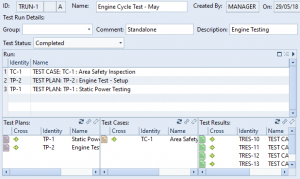

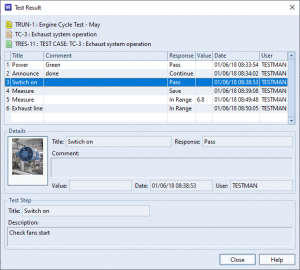

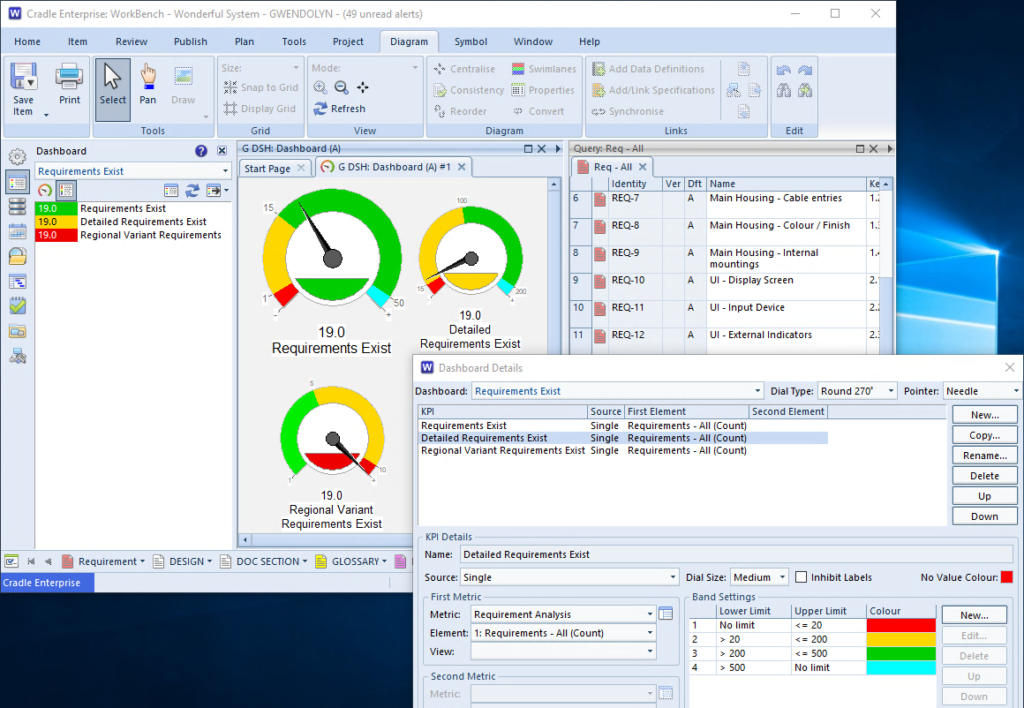

As part of our validation activity, we will need a way to measure the characteristics that we have decided will be used to describe quality. In our example, we could subject our ledger to an accelerated weathering simulation with cycles of varying intensities of UV light, humidity and temperature. We could then check the integrity of the volume’s bindings, its pages and the contrast of the ink and the page.

With defined quality metrics and measurable values for each metric, the quality of each product can be judged against the metrics and accepted or rejected.

What If I Can’t Measure It?

There are some things that are much more difficult to quantify. However that should not stop us trying. A customer requirement to have a soft-touch finish on their product could be met by covering it in foam padding, or a velvet cover. These might be acceptable for a chair, but not much use on the handle of a cold chisel. For this quality metric, the customer wanted something to absorb vibrations and so make the tool more comfortable to use. There may be measures of ‘softness’ in terms of compressibility and stiffness, but these may be difficult to use as quantities; You could argue velvet feels ‘softer’ than a rubberised plastic handle, but the latter will compress more than the former.

Be SMART

In some cases to make the requirement SMART (Specific, Measurable, Attainable, Realisable, Traceable) the specific and measurable aspects may be done by comparison, or actually specifying part of the ‘solution’ in the requirement. Whist well written requirements should not mandate the solution. They should be a detailed expression of the needs, allowing the design and production to choose the most appropriate solution. However, this is not always possible. “The chair must be covered in velvet“, is really a constraint, it is unambiguous and would allow the end product to be undeniably validated. However, we could still debate the “plushness” and whether it is made from artificial or natural fibre.

Be Clear

In the case of the chisel, the main product finish may be specified by meeting a design constraint; such as British Standard BS 3066. This will ensure hardness of the cutting edge impact resistance will be suitable. However, the optional handle would not be covered.

We could write, “The handle should be soft to the touch providing good grip and absorbing at least 50% of the impact force when compared to an uncovered chisel. Properties comparable to the material used on the Club hammer CLBHM002 in the same range should be considered.” This time the requirement is not mandating the same material, it is allowing practical consideration as to what is possible in the manufacturing environment. It does invoke a measurable aspect whist not needing to meet specific values. It also highlights the reasons for the specification, to provide grip. If this came to a point of discussion and the supplier covered the handle in PTFE encased foam, it may be soft but would not be considered an aid to grip. However, a rubber, or texturized plastic would both pass muster.

Strive Towards Acceptance

The book on requirements management might tell you about being precise. Even in the trivial examples given we could all spot flaws. How long does the handle need to last? Does the product have to be water repellent? It would be terrible using a chisel with a lovely shock absorbing handle, if it became cold and soggy at the first sign of rain, or when rinsing it clean.

As either a customer or supplier we can mitigate against these problems, by taking a more agile approach to the whole design. Before final design and definitely before production, a round of review of design and validation criteria should be undertaken. Samples of the handle material can be shared with the customer. The baselined requirement can be updated with a new version, to explicitly state “The handle shall be manufactured from a suitably damage tolerant material, providing a good non-slip grip such as EVA – an ethylene polymer“. We have then full traceability that the requirement was updated as a result of design review. We also have a constraint that can be validated.

A Word of Caution

Whilst communicating with potential suppliers, you also need to ensure a building of trust. Ensure each side has all the correct confidentiality agreements signed. Make sure it is clear who owns the IP on any design. Whilst researching this article, the need to keep your discussions under wraps was highlighted, by Footprint Tools. If details are handed out too freely, you may find a supplier you end up not using plus a competitor buyer, beats you to market. Unfortunately you may also find if your chosen supplier is less than trustworthy they could use your design to create product for another buyer. Quality in this case applies to the contract and the trust of everyone in the engineering lifecycle chain.

Reference:

- EVA – Ethelyne-Vinyl-Acetate

- Tool handle manufacture http://footprint-tools.com/product/cold-chisels/

- Robert Southey – Credited with the original story of the 3 bears, that became the Children’s story of Goldilocks. He was one of the lakes poets, living for a time at Greta Hall, Keswick, Cumbria

- Magna-Carter image used under open licence